Blogs

Looking for the old Kontakan site? It has been moved to Berkada.com.

Grow your friends list in Kontakan. Invite your friends to join our site! Click here to send an invitation.

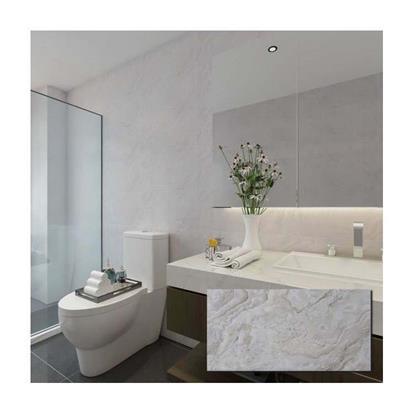

The installation of tile paving is a major source of concern for everyone. The aesthetics of a home are greatly influenced by how well the wall tiles and floor tiles are pasted. Despite the fact that the traditional construction method is simple to use due to a certain proportion of cement mortar, if the operation is carried out in an unreasonable manner at an early stage, it is easy to have ceramic tiles, hollowing, and even direct falling off. On the other hand, the thickness of cement mortar applied to the wall is typically between 10-15mm, which is considered to be relatively thick. Later, after a long period of accumulation and improvement, a more mature thin paste method has emerged. It is referred to as the thin paste method because the thickness between the ceramic tile and the wall is only about 3mm after construction, which allows for some space savings.

What is the ceramic tile thin paste method?

The thin tiling method is the most widely used tiling method. The Thin Paste Method was developed in Germany. In reality, it is only a wall tiles china paving process when compared to the domestic thick paste method. The thickness of adhesive used in China is 15–20mm, whereas the thickness of adhesive used in the United States is only 3–5mm after scraping the base adhesive into stripes by the thin pasting method.

What is the difference between the thin paste method and the traditional paste method?

1. Different materials are required.

Thick paste method: Cement mortar must be prepared by mixing cement and sand with water before use. As a result, the quality of cement mortar will be affected by the reasonableness of the cement ratio, the accuracy of the material dosage, and the uniformity of the mixing.

Thin paste method: a ceramic tile adhesive is used during the paving process, and it can be used directly with water. There is no need to mix cement mortar on the job site. The quality standard is simple to understand, the bonding strength is relatively high, and the construction efficiency has been greatly improved.

2. Requirements for different technical levels

It takes experienced and skilled technical workers to pave with the thick paste method. It is easy to create problems when mixing cement and sand on site, and the mixture has a high degree of mobility and randomness, both of which are characteristics that affect the quality. If the paving process is not in place, it is easy to cause problems such as hollowing and cracking of ceramic tiles, and it is difficult for Pavers with insufficient technology to pave ceramic tiles smoothly.

Thin paste method: Because of the straightforward operation, professionally trained workers can use ready-mixed porcelain tiles price adhesive for paving, resulting in a significant increase in the efficiency of the paving process.

3. There are various process requirements.

Thick paste method: the wall must be treated and roughened before the paving can be completed; tiles must be soaked prior to installation.

Thin paste method: in addition to the same requirements for base treatment and roughening of the wall, it has strict requirements for the flatness of the wall. In most cases, it is necessary to level the wall, but it is not necessary to soak the ceramic tile.

4. Different labor consumption patterns

Thick paste method: the general thickness is 10-20mm, and the cement sand ash content is 15-20kg, which increases the burden. From the standpoint of construction, the bricklayer aspires to be visually appealing while also ensuring high quality. Typically, 8 square meters can be paved per day.

Thin paste method: the thickness required is only 3-5mm. There is some empirical evidence. The ceramic tile adhesive weighs 1.6kg per square meter and 1.6kg per millimeter. What exactly is three millimeters?5 kilograms. What is 5mm in length?8 kg in weight. When the base course is leveled, 20 square meters of pavement can be laid in a single day.

What are the advantages of employing the thin paste method?

1. The construction efficiency of workers is high, and the requirements for bricklayer proficiency are relatively low; 2. Because the thickness is much lower, it can save a significant amount of space.

The thickness of ceramic tile adhesive used in thin pasting method is only 3mm, and the strength is also very high, resulting in a reduction in the amount of space occupied; 3. More importantly, the quality is better, the hollowing rate is very low, the firmness is extremely strong, and the price is slightly expensive but acceptable.

A friend inquired whether the thin paste method was the best option, regardless of the cost. According to Zhongtao Jun, it should be interpreted in this way. First and foremost, the thin paste method is intended for wall construction only, and floor tiles are not required. Second, only polished bricks and vitrified bricks with extremely low water absorption are suitable for use with the thin pasting method. Due to the problem of water absorption, this type of bricks is paved with cement mortar, and the cement will slide, resulting in hollowing and falling off. As a result, a ceramic tile binder should be used. Additionally, when working with ceramic tiles with particularly large specifications, it is preferable to use the thin paste method.

When it comes to ordinary glazed tiles, traditional methods can be used. Because of this, when an owner purchases ceramic tiles, he or she can easily determine the appropriate paving method as long as he or she asks whether the tiles being purchased are glazed or vitrified.

Additionally, for some upside-down tiles (such as those above the door frame, with the tiles facing down), which are greatly affected by gravity, ceramic tile adhesive can be used as a form of reinforcement.

It is more technical for workers to use the thin paste method. Because of the high adhesive strength, it is difficult to straighten out a crooked edge after it has been pasted. This is not the same as the traditional paste method. If you are dissatisfied, there is still the possibility of obtaining a refund. It is necessary to have highly skilled workers for this characteristic. Of course, some small businesses opt for a middle-of-the-road approach, such as mixing a small amount of cement mortar into the ceramic tiles china binder. As a result, both the cost and the technical requirements are decreased. Although this is not cutting corners, it can no longer be referred to as the thin paste method. Ceramic tile paving used to be a thick paste made of cement mortar. Now there is a new ceramic tile glue thin paste method that can firmly paste tiles, save labor and materials, effectively solve the problems of hollowing and falling off of ceramic tiles, effectively replace the traditional paste method, and gradually become more popular.

Topics:

porcelain tiles price

Be the first person like this

Be the first person to like this.

Be the first person like this